Setup Training, Chassis settings for the iRacing FR2.0

Springs, Dampers and ARB

Intro:

The term Vehicle Dynamics describes a field of art, science

and engineering that attempts to describe the behavior of a vehicle while in

motion. Like Aerodynamics, it is a highly complex field of study. There are

thousands of pages written about the subject. The book, Race Car Vehicle

Dynamics by Milliken and Milliken is considered one of the most important

collections of information. Below are a few links for those interested in doing

a lot of reading and thinking,

Fortunately, we don’t need to design the car. We simply need to understand how to make it

go fast! So this article (based on significant

testing) will focus on some very basic core principles that can be applied in

the process of building a setup that will allow our best lap times for the

FR2.0.

Vehicle Dynamics and Chassis Set Up is pretty much all about

making the car go thru corners quickly and that is highly related to how the

weight on the tires changes through the corner.

So, since the car is essentially “held up” with spings, it

is the springs that we will address first.

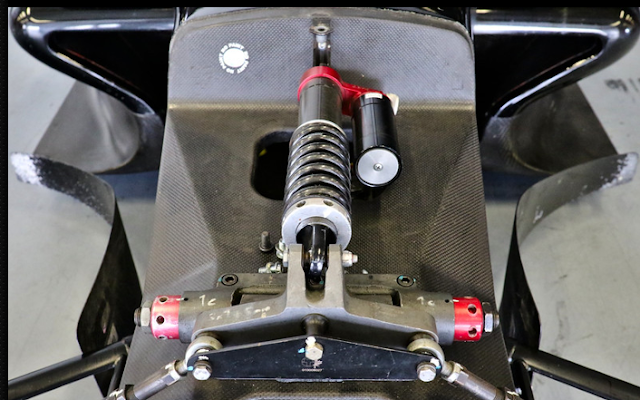

Formula race cars generally use a “coil over” spring or

springs. The coil spring is located

around or over the damper. (Americans call them shocks—Europeans call them

dampers).The most typical is one coil over assembly (spring and damper) for

each wheel. A typical design (if there is such a thing) is shown below.

The coil over is connected to the wheels thru a quite clever and complex series of rods, and rockers. Most of this complexity is so that the coil overs can be located inside the body, so as to improve aerodynamics. The typical rear set up is often quite similar to the front.

Many iRacing drivers are familiar with the Pro Mazda that

uses this conventional four spring design.

The F2.0 uses a special “monoshock” design for the

front. Instead of two springs, the

entire front is held up with one coil over. There are a few variants of the

monoshock concept, but the principle is simple. The first photo below is a

Dallara IndyCar prototype. The second is one of the early FR2.0.

Photo of FR2.0 Front “Monoshock” and Spring—see link: http://www.motoiq.com/MagazineArticles/ID/4322/PageID/10853/LRS-Formula-at-Magny-Cours.aspx

Europeans familiar with the Mygale Formula BMW will know

that it too used a monoshock to save weight. The Mygale design was different in

that it used a more traditional ARB rather than the sliding crank.

On a conventional design, each wheel is supported by it’s

own spring/damper allowing wheel movement on one side independent of the other.

Under straight line braking for example, both wheels move the same distance,

compressing both of the spring/damper coil over assemblies. When the car rolls

in a turn or strikes a curb, only one wheel moves.

To improve handling, and reduce body roll, the Anti Roll Bar

or ARB is added to the design—essentially connecting the two wheels with a

torsion bar. Now the wheels no longer move independent of each other. When one

wheel goes up relative to the chassis, the torsion bar is twisted and applies

an upward force to the other wheel. (Keep in mind that the wheel generally stays on the ground, so when we

refer to the wheel going up—it really means the chassis is moving down relative

to the ground and the wheel is moving up relative to the chassis. )

Here is a Youtube about ARB’s.

This conventional design is what is used for the rear on the

FR2.0.

But, with the front “monoshock” things are quite

different. Each wheel is connected to

other via the rods connected to the solid “crank”. Under straight line braking

for example, both wheels move the same distance, rotating the “crank” and

compressing the single spring/damper coil over assembly. When the car rolls in

a turn or strikes a curb, since they are connected, when one wheel moves,

instead of the “crank” rotating, the “crank” slides on a shaft and compresses a

spring. The lateral spring, hidden from view in the photo is inside the sliding

mechanism. So, when the car rolls in a

turn, when one wheel moves up, the other moves down with the relative motion

resisted by the hidden spring.

From our point of view, the most important consideration/s

regarding this design are:

A--The roll resistance of the monoshock

assembly in the iRacing FR2.0 is generally much lower than would be the case

for a conventional two coil-over with ARB design. The roll resistance of the front suspension for the iRacing FR2.0 is

also not adjustable. (In real life the internal lateral spring can be changed

and adjusted.) The roll resistance of the front is only slightly affected by

the spring rate on the coil over.

B--There

is no damping forces against chassis roll on the front assembly. All of the damping

forces in chassis roll is accomplished with the rear dampers.

One thing for sure—the design on the FR2.0 works very well

and properly setup, handles as well or better than a car with the more

conventional design.

Just for fun, let’s take a

look at how the suspension interacts. Basically, I increased the Pushrod length

on the right rear from 21.450” to 21.481”. This is an increase of 31 thousanths

of an inch, or 0.8 mm. This would be like having a “weight jacker” like the

IndyCar uses, or would be like adding “wedge” on an oval. Weight is transferred

diagonally. (Starting weights were 278# front and 369# rear)

With the rear ARB disconnected, the RR weight

was increased by 12 pounds. The LF was increased by 121 pounds. The RF and LR

corner weight was decreased by 12 pounds each.

This was good news in that the car behaved pretty much like a typical race car.

This was good news in that the car behaved pretty much like a typical race car.

Now, I connected the rear

ARB, set on a low P1-Stiff setting. Results are shown below. Weight change on

each “corner” was cut in half to 6 pounds, with the ARB doing it’s intended

function, as it was “twisted” to 13.8 ft-lbs.

All this exercise provides is some insight into the function

of the ARB. By adding “Wedge” to the the

RR, the RR is placing a torque on the ARB that pushes down the LR. So the ARB

transferred 6 pounds (50% of the normal cross weight transfer) from one side to

the other on both the front and rear.

I

did the same test with an ARB setting of P4–Stiff which resulted in an ARB

torque of 21.4 ft-lbs. and a transfer of 66% of the normal cross weight

transfer.

When the chassis rolls in a right turn, as opposed to the

weight jack or wedge test, the ARB would be pulled up (relative to the chassis)

making the RR suspension more stiff, and

would reduce the weight on the inside LR and increase the weight on the LF.

This would reduce body roll, make the rear have less grip and the front have

more grip.

Do not underestimate

the effect of the ARB on the iRacing 2.0. Increasing ARB will be most powerful

from Mid Corner to Corner Exit and will dramatically decrease the traction

available on the inside rear tire under acceleration.

Here is a post by my friend, Diederik Kinds who is a Race Engineer on a team that ran the FR2.0:

I worked with this FR2.0 for years. It has an adjustable front ARB system with Bellevilles as depicted in the parts manual, but the pics are not the Tatuus FR2.0 but they look very similar.

There are a lot of Belleville variations for the FARB (preloaded and non-preloaded), none of which are modelled in iRacing.

When the iFR2.0 came out I immediately shot off a mail to iRacing about some setup inconsistencies - 1 about damping settings (bump and rebound were switched) which were subsequently adjusted and the other about lack of FARB adjustment.

I will just copy/paste the answer here:

"In regards to the FARB, essentially the stack system functions like a controlled, and exceedingly stiff, slack rate around center. Because most settings are much too stiff for our numerical integration step we've pegged bar rate to coupled installation stiffness and chassis torsion. This method was the only one, within the iRacing constructs, to allow all available RARB options. The alternative options would have been more restrictive."

On should always keep in mind that settings affect the car the way that iRacing chooses, "within iRacing constructs" as mentioned above ---and their choices may change from time to time. So always test to confirm settings continue to do what you think they do. The iRacing FR2.0 is an iRacing simulation of the real FR2.0.

Here is a post by my friend, Diederik Kinds who is a Race Engineer on a team that ran the FR2.0:

I worked with this FR2.0 for years. It has an adjustable front ARB system with Bellevilles as depicted in the parts manual, but the pics are not the Tatuus FR2.0 but they look very similar.

There are a lot of Belleville variations for the FARB (preloaded and non-preloaded), none of which are modelled in iRacing.

When the iFR2.0 came out I immediately shot off a mail to iRacing about some setup inconsistencies - 1 about damping settings (bump and rebound were switched) which were subsequently adjusted and the other about lack of FARB adjustment.

I will just copy/paste the answer here:

"In regards to the FARB, essentially the stack system functions like a controlled, and exceedingly stiff, slack rate around center. Because most settings are much too stiff for our numerical integration step we've pegged bar rate to coupled installation stiffness and chassis torsion. This method was the only one, within the iRacing constructs, to allow all available RARB options. The alternative options would have been more restrictive."

On should always keep in mind that settings affect the car the way that iRacing chooses, "within iRacing constructs" as mentioned above ---and their choices may change from time to time. So always test to confirm settings continue to do what you think they do. The iRacing FR2.0 is an iRacing simulation of the real FR2.0.

Spring selection for the FR2.0 is relatively simple. For the

front spring, you can choose 700#, 800# or 900#. For the rears, 800#, 900# or

1000#.

The “correct” choice depends a lot of Driver Preference.

Notice I do not use the term Driver Style.

Our high speed “test track” for aerodynamics was Talladega

Speedway. For testing of the car in corners,

we go to the Centripetal Circuit. (Centripetal force is defined as, “The component of force acting

on a body in curvilinear motion that is directed toward the center of curvature

or axis of rotation,” while centrifugal force is defined as, “The

apparent force, equal and opposite to the centripetal force,

drawing a rotating body away from the center.

So we are testing the Centripetal force produced by the tires of the

car.) I generally go to the lane fourth from the outer one. We run the

test at 123-124 mph at part throttle, burning 0.5 gallons of fuel—then we

measure tire temps to see changes due to changes in spring rates.

Test 1: Running “full” 31/12 downforce, with 700# front spring and

800# rears, with an ARB setting at P1-Stiff.

Result: Front Total 1036; Rear

Total 1048, slight increased wear and temp on RF. Essentially close to balanced

or “neutral” at part throttle. (See

above)

Test 2: Same settings as Test 1 except: 800# front spring and 800#

rear spring. Same result as Test 1

Test 3: Same settings as Test 1 except: 900# front spring and 1000#

rear spring. Same result as Test 1

Conclusion: While

spring rates will dramatically affect handling and “feel” when the car is in

“transition”, slowing down, accelerating, entering the corner or exiting the

corner; spring rate choice will have less effect on the car’s grip and handing

in a “steady state” turn. This may surprise many, including oval track racers

who change springs to effect handling, but keep in mind that even on an oval track,

there is a significant period of time when the car is in “transition”.

A useful learning exercise is

doing this test and noting the way the car responds to throttle. The car will

turn more tightly when the throttle is released and then will want to track out

at full throttle, with no change in steering input. So the car can be steered

with throtlle by changing weight transfer from rear to front and back. Learning

how to control this will make you faster.

The higher spring rates will

result in a faster reaction to the throttle’s steering effect..

Test 4: Same settings as Test 3 except: ARB set at P5-Stiff. With

maximum stiff springs and maximum ARB, the car was quite “twitchy” with very

fast reaction to changes in throttle. Car spun when I released throttle at end

of test. (See above). Result: Front

Total 1041; Rear Total 1064, RR tire wear now same as RF. Note higher LF tire

temps resulting in more weight transferred there by the stiff ARB. Essentially still close to balanced or

“neutral” at part throttle but more tending toward oversteer.

A good video about spring rates:

Now let’s address the Dampers.

The video will define some terms:

Simply put, springs primarily determine the distance the

suspension travels and dampers primarily determine the speed the suspension

travels. Note I said, “primarily”. With a given force, a stiffer spring will be

compressed less, so a stiffer spring does not need to travel as far—hence,

given a certain damper setting, the stiffer spring will absorb a given force

more quickly. In addition, in a “dynamic” scenario, where force is momentary or

short in duration, a stiffer damper can

reduce the distance the suspension travels.

Don’t over-simplify and don’t over-complicate the picture.

Above is the iRacing Setup Screen showing Maximum Compression

(Bump) 0 and Maximum Rebound Stiffness 0.

Following is the iRacing Setup Screen showing Minimum

Compression (Bump) 40 and Minimum Rebound Stiffness -2. There is 40 “clicks” from Maximum to Minimum

Bump. There are 8 “clicks” (0, -.25, -.50 etc to -2.0) from Maximum to Minimum

Rebound.

NOTE: THERE IS A

BIT OF CONFUSION REGARDING THIS, AS “RIGHT” CLICKING DECREASES BUMP AND

INCREASES REBOUND DAMPING. (Some people assumed that right clicking always

increases the setting—this is NOT the case for Bump damping settings. I WILL

ADDRESS THIS WITH SOME TEST RESULTS LATER.

Below is a sample real iRacing Setup Screen (Sample 1) (This one in the hands of an outstanding driver matched the world record at TT conditions.)

Below is another real iRacing Setup Screen (Sample 2) with “softer”

Bump Damping and considerably “softer” Rear Rebound Damping.

It is often a surprise that the typical racing damper has

more damping force in Rebound than in Compression Bump. The reason is that the

spring absorbs most of the compression force applied by bumps and cornering,

while the spring is working against the damper in Rebound. Hence, choosing the correct Rebound setting is

often more critical. 40 clicks for a

smaller force makes each click less in magnitude for Bump compared to 8 clicks

for a much larger damping force.

Here, following are two charts. The first is a graph showing

data from Penske Shock’s dynometer for custom shocks they built according to

specs I provided. The shocks were for a very competitive SCCA Formula Vee I

raced and won with at Summit Point.

The next graph illustrates the dampers on the iRacing 2.0,

for the purpose of understanding the damper settings. I inserted notes on a

graph provided by Penske Shocks for a “typical” double adjustable damper. (The

actual data (force and velocity) is not exactly the same as the FR2.0.

OK, let’s go back to that earlier NOTE: THERE IS A BIT OF CONFUSION REGARDING THIS, AS “RIGHT”

CLICKING DECREASES BUMP AND INCREASES REBOUND DAMPING. (Some people assumed

that right clicking always increases the setting—this is NOT the case for Bump

damping settings. I have tested the

dampers extensively running telemetry at the very bumpy Sebring International

and Lime Rock where the car goes airborne. The test at Sebring was to primarily test if

the dampers could be set at extremes that would “jack up” the car or “clamp

down” the car over a bumpy track. The results indicated that neither was an

issue.

The test at Lime Rock provided an excellent “picture” of the

damping. Below is the first result with Maximum Bump and Rebound Damping.

Next, following is the result with Minimum Damping. In both results, you can clearly see the car “launch”

and go fully airborne with a bit of “twist”.

As the car “lands” first on the left tires, it is clear that the setting

of 40 compression allows much faster and larger suspension travel (same

springs) than the 0 setting. With the lesser damping setting of 40, the damper

is traveling almost twice as fast and the car falls 0.80” inches (20mm) closer to the ground, almost bottoming

out.

One can also see clearly that the car bounces significantly

less with the higher compression and rebound damping. Once the car “bottoms”, the subsequent rise

is significantly more with the lower rebound setting, and “overshoots” by more

than 0.50” above equilibrium.

Well, that’s a lot of info, but let’s summarize as a group of three ABC's.

Springs

A---Stiffer springs reduce suspension travel and chassis

roll, and make the car faster to respond to initial steering input. (Although

this effect is less for changes in the front monoshock.)

B---Stiffer springs makes weight transfer to the front tires

under braking occur faster. (This may require more front brake bias to avoid

rear wheel lockup or conversely may reduce the possibility of front brake

lockup.) And weight transfer to the rear

under acceleration occurs faster. However, most often for maximum drive out of

a slow hairpin, weaker springs on the rear often allow for better acceleration.

C---Stiffer springs often allow the tires to come off the

ground or “unload” on a bumpy track as their static compression is less. If the

track is bumpy, stiffer springs may reduce grip significantly. (Watch the

video.) Stiffer springs reduce the likelihood of the car bottoming when hitting

a bump.

Dampers

A--Stiffer front and rear bump and rebound damping reduce

suspension travel and make the car faster to respond to initial steering input.

(Although this effect is less for changes in the front monoshock.) Reducing

rebound damping can make the inside tires have more grip in a turn.

B--Stiffer front and rear bump and rebound damping makes

weight transfer to the front tires under braking occur faster. (This may

require more front brake bias to avoid rear wheel lockup or conversely may

reduce the possibility of front brake lockup.) The first adjustment is typically to reduce the rear rebound to keep the rear

stable under braking—this will also help to keep the rear tires on the ground

when cresting a hill.

C--Stiffer front rebound and stiffer rear bump damping will

make weight transfer to the rear under acceleration occur faster. (The stiffer

front rebound is sometimes counter-intuitive. And, you may NOT want fast weight

transfer if you are experiencing wheel spin.)

Anti Roll Bar (ARB)

A--The rear ARB will reduce chassis roll. Stiffer settings

reduce more.

B--The rear ARB will take weight from the inside rear tire and transfer much of that to the inside front tire.

C--The rear ARB will dramatically change the “balance” of

the car as there is no adjustment to the front.

Keep the setting the least stiff as possible (Do not disconnect) while

still achieving desired rotation from apex to track out. (We will focus on this

again in the article about the locking differential.)

The following chart will provide some insight as to the

ranges for spring choice, damper settings, and ARB settings. You might experiment with the “Possible Combo’s”

settings, changing damper and ARB settings for given spring choices, but they are not intended to be recommended “baseline” settings. You

will need to consider the other important settings for camber, toe, tire

pressure, and differential settings—all to be covered in future articles. All of these settings are related. Your “baseline”

settings for you is what matter. (You will recall, I suggested having three—which would then allow you

to have a starting point for different groups of tracks.) But to create a baseline for you, you will require a bit of experimenting and

testing.

You will recall that I mentioned that chassis settings often have to do with driver preference. I tend to think of drivers fitting into one of two major categories:

The “High Frequency” types that probably relate to driving

racing karts. They prefer the car to be stiff and react to inputs very

quickly. They usually have fast reflexes

and enjoy making numerous and rapid corrections to steering, braking and

throttle inputs as necessary when they exceed the limits.

The “Low Frequency” types that probably relate more to

piloting airplanes. They prefer the car to be less stiff and react to gradual

and deliberate inputs, gradually. They desire the car to navigate the corners

with stable and deliberate inputs to create a smooth arc of travel, with few corrections

being necessary—seeking to always to reach but not exceed the limits.

Both types can be very fast—but the set up needs to “fit”

their preference. To be fast, you must keep the car as close to the limit as

possible at all times. And, remember that a confident driver is a fast driver!

One final note. iRacing has a minimum ride height. The iRacing FR2.0 generally is fastest with the lowest front ride height allowed that will not result in the car bottoming out, hitting curbs when straddling them, etc. Rear ride height is determined by the desired rake and the same restriction of not bottoming out. 0.4 to 0.6 inches static rake is a good place to start. Softer springs tend to result in lower dynamic ride height, but often require a bit more compression bump damping.

You can test ride height with telemetry like Motec or Atlas, but a poor man's quick way is to simply use the iRacing replay camera, adjust the chase view so that your eye is at road level and watch the air gap under the car. iRacing will even display sparks when you bottom out!

A little complicated. Will have to revisit.

ReplyDeleteBut very informative! I've been wondering if I'd ever understand the basics of spings and shocks for a very long time!

Thanks!